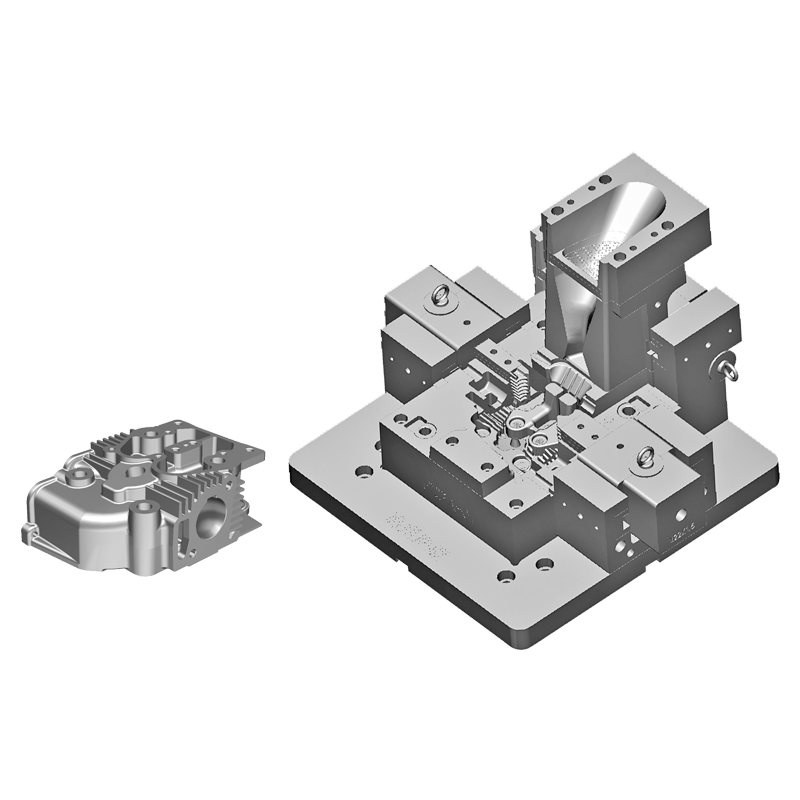

Precision and consistency are two of the most critical attributes of automotive moulds that significantly impact the quality and performance of the final automotive components.

Precision in Automotive Moulds:

Precision refers to the level of accuracy and exactness with which an automotive mould can shape a component according to its design specifications. Achieving precision in moulds is essential for several reasons:

Fit and Functionality: Automotive components must fit together seamlessly to ensure the overall integrity and performance of the vehicle. Precision in moulds ensures that each part is manufactured with precise dimensions, allowing for accurate and smooth assembly during the vehicle manufacturing process.

Tolerances and Clearances: In modern vehicles, many components must work together with minimal clearances and tight tolerances. A slight deviation in dimensions can lead to misalignment or interference, affecting the functionality and safety of the vehicle. Precision moulds ensure that parts meet these stringent tolerances consistently.

Surface Finish: The surface finish of automotive components can significantly impact their appearance and performance. Precision moulds create smooth and flawless surfaces, reducing the need for additional post-processing steps like sanding or polishing.

Structural Integrity: Automotive moulds help ensure the structural integrity of components, particularly those used in critical areas such as chassis, suspension, and safety systems. Precisely moulded components are less prone to structural weaknesses or defects that could compromise the safety of the vehicle and its occupants.

Consistency in Automotive Moulds:

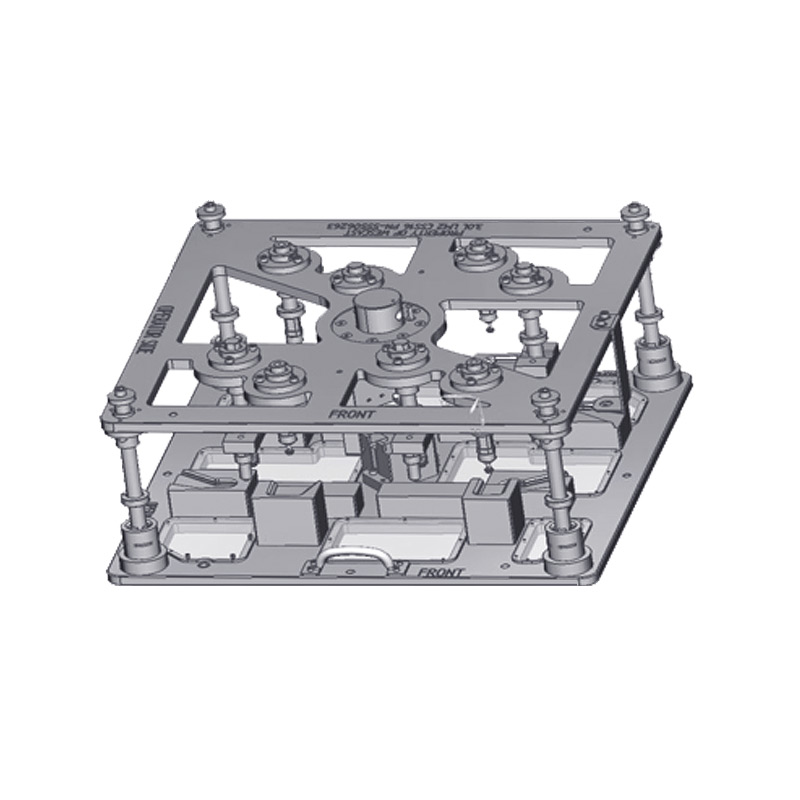

Consistency refers to the ability of automotive moulds to produce multiple identical parts with uniformity, batch after batch. Consistency is vital for several reasons:

Quality Assurance: Consistency ensures that each part produced by the mould meets the same high-quality standards. Manufacturers can rely on the consistency of moulds to deliver products that perform consistently and reliably in the field.

Batch Production: In mass production scenarios, automotive components are manufactured in large quantities. Consistency in moulds allows for seamless batch production, as each part matches the same specifications, reducing the need for constant adjustments and inspections during production runs.

Assembly and Repairs: Consistent parts are easier to assemble during vehicle manufacturing, as well as during repairs and maintenance. Automotive technicians can confidently replace damaged components with identical parts, ensuring compatibility and preserving the vehicle's original performance.

Brand Reputation: Consistency in the quality and performance of automotive components contributes to a positive brand reputation. A vehicle manufacturer known for consistently producing reliable and durable vehicles gains customer trust and loyalty.

Pусский

Pусский Español

Español